A Custom-Made Diamond Scribe for Particle Manipulation

Sometimes it is necessary to precisely mark the location of a micrometer particle(s) on a hard surface like silicon, pyrolitic carbon or a glass slide. The scribe must be small so that it does not obscure the field-of-view and the particle that is being marked. The scribed lines must be fine and leave minimum residue.

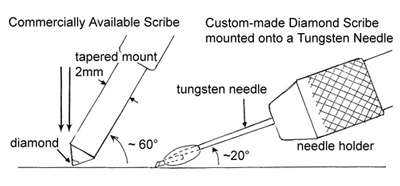

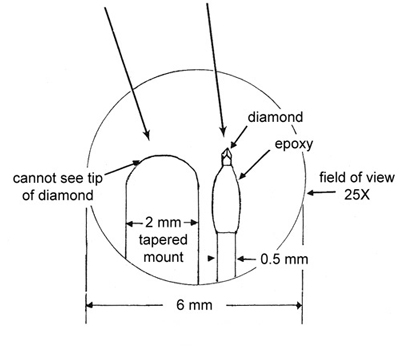

The commercially available diamond scribes in their 2 or 3 mm = d, tapered mounts are inadequate for marking the location of micrometer particles because the diamond cannot be seen when the scribe is placed in its minimum scribing position of >45°; one can only see the 2 or 3 mm wide mounts that fill one-third of the field-of-view at 25X magnification (see Figures 1 and 2). With these diamond scribes, it is only possible to estimate and draw about 2 lines/mm using the 2 mm mount and 1 line/mm for the 3 mm mount.

A far better scribe is the commercially available diamond knife, about 1 x 2 x 0.25 mm in size, with a retractable holder sold by Electron Microscopy Sciences. It is excellent for marking locations of particles. It is small, clear, and does not obscure the field-of-view; however, it is very expensive.

A similar unmounted diamond (~0.25 x 0.25 x 1.75 mm) used to be available through McCrone Microscopes & Accessories (catalog #124). It is possible to scribe about 8 lines/mm with this diamond. It can be attached to a tungsten needle or stainless steel tubing as follows:

Mounting a Diamond on a Tungsten Needle

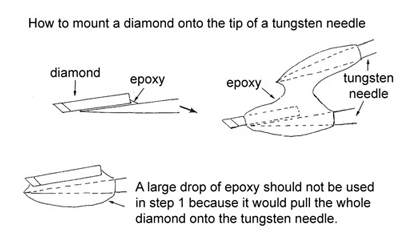

Step 1. The diamond is picked up by a medium-to-coarse tungsten needle* that has a tiny amount of fresh epoxy (Hardman® 3-5 Min. Epoxy) on the tip. This small amount of epoxy will hold the diamond in place while the microscopist can align the diamond with another tungsten needle, so that ¼ of the length of the diamond protrudes over the needle.

Step 2. When the epoxy hardens, a second coat of epoxy is put around the needle and diamond (see Figure 3). A third coat of epoxy may be required.

* Teetsov, A., “Preparation and Use of Needles and Micropipets for Handling Very Small Particles,” Microscope 47, pp. 63-70 (1999)

Using a Diamond Scribe to Remove Hard Residues

Mounting a Diamond Inside Stainless Steel Tubing

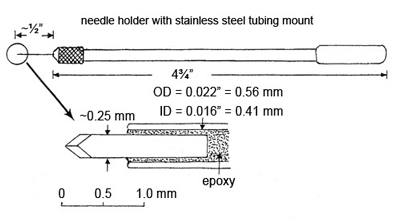

Twenty-four gauge stainless steel tubing with an inside diameter of 0.016″ (0.41 mm) can be purchased in 1 foot sections from McMaster-Carr* and cut into 1 1/32″ lengths. The tubing is cut with a diamond blade and the ends are polished on a circular sander. The diamond is epoxied into one end of the tubing (see Figure 4). The 0.022″ (0.56 mm) OD tubing fits nicely into the standard needle holder.

* McMaster-Carr 2004 catalog, #5560K66.

Cleaning the Diamond

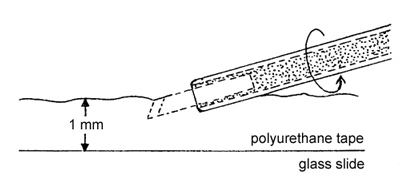

1-mm thick polyurethane tape** is excellent for removing residues off the six exposed surfaces, as well as from the diamond holders. The diamond is rolled on and in the tape. The tape will not damage or leave a residue on the diamond (see Figure 5).

** McMaster-Carr 2004 catalog, #75845A72 – ½” wide, 0.063″ thick.

Removing Residues from Glass Surfaces

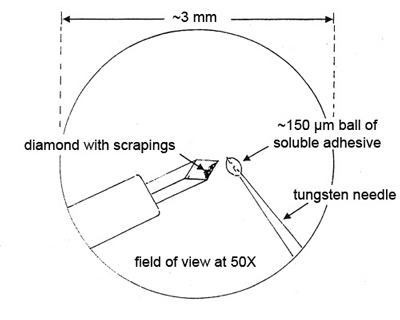

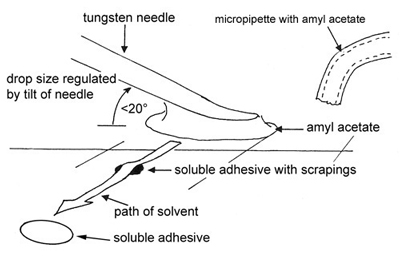

In addition to scribing lines, the diamond is also used to scrape hard residues off surfaces like glass or metal. First, the diamond’s six exposed surfaces are thoroughly cleaned as shown in Figure 5. The edges of the diamond, not the fine point, are used for scraping. The scrapings collected on the diamond edges are removed with a 100-200 µm = d ball of soluble adhesive (see Figure 6). For elemental analysis, the adhesive plus scrapings are placed on a polished carbon planchet and the adhesive dissolved with a few ~5 nL drops of amyl acetate. The scrapings will remain essentially in place if the drops of solvent are passed evenly over the samples. Each drop is allowed to go to dryness before the next one is passed. This step is repeated until almost the entire adhesive is dissolved (see Figure 7).

Note that, to remove the scrapings, the tip should never be dipped into a nL drop of solvent on the substrate, because the solvent can migrate up the diamond’s sides and take some of the scrapings with it.

It is useful to make more than one scribe. Save the best scribe for scraping residues, and use the others to scribe and cut.

Comments

add comment