Adventures in Communication: Why No One Understands Me.

It is impossible to deny the importance of any microscopy technique as applied to research and problem solving. However, the foundation to all our endeavors is and must be communication. What we perceive and understand with the photon and electron remains a mystery until it is communicated to another.

Communicate is from the Latin verb, communicatus, meaning “to participate.” Merriam-Webster defines communicate as, “to transmit information, thoughts or feelings so that it is satisfactorily received or understood.” It is the satisfactorily received or understood aspect of this definition with which we constantly struggle.

A central aspect of successful communication is having shared goals and terms.

A helicopter pilot found himself confused in a fog over a major northwest city. Hovering next to a tall building, he quickly drew a crowd at the upper floors. He held up a clipboard with the printed message: “Where am I?”

It was a matter of seconds before a pair of binoculars were located, the message read and a reply formulated. Holding up large poster board sheets, the office people responded: “You’re in a helicopter.”

The pilot immediately set a course, flew safely to the nearest airport and landed.

His amazed passenger asked the pilot how that information helped. The pilot replied that the information was totally correct and absolutely useless and where else could he be but the Microsoft building.

There have been times that I have felt like the office dwellers.

Twenty years ago my company was selling delustered polyester cubes to a spinning and weaving company. Problems arose at one point during the customer’s operations and an increase in defects occurred. The goals were quickly defined: we wanted to sell them more polyester; they wanted to solve the problem that was reducing productivity. During the drawing stage, some areas of the spun fibers refused to be drawn. This transformed the smooth fiber line into something resembling little sausages on a string. These sausages caused the fiber line to break during the weaving operation, resulting in down time and additional expense.

Examination of the both the cubes and fiber showed a normal dispersion of the TiO2 delusterant. The gross physical properties such as intrinsic viscosity, acid number and bulk melting point were normal. Portions of lots returned from the fiber manufacturer ran fine in our pilot spinning lab.

Examination of the defect with light microscopy identified the cause. Many of the little sausages possessed an amber streak of material. Hotstage microscopy and solvent testing identified the streak as degraded polyester. Degraded polyester has different physical properties and it would draw differently creating the defect.

Memos were exchanged and a task group was formed to eliminate the degraded polyester. Inspection of the spinning operation found some of the fiber spinnerets, multi-holed steel plates kept at elevated temperatures, were coated with a thin layer of degraded polyester. This build-up would eventually be picked up by the exiting fiber line and could create the defect. The customer called the defects with the degraded polymer “slubs.” This suggested they were familiar with this problem.

Changes were made to the polyester manufacturing and to the spinning process. Samples for microscopical analysis arrived almost daily. The defects were cross-sectioned, and sorted for further testing. Those with amber slubs were dissolved in hexafluoroisopropanol. HFIP dissolved the normal polymer, but the degraded material simply swelled. Those without slubs were melted with the hotstage at approximately 260°C. These experiments often revealed a strip of highly birefringent material which melted substantially above the 260°C range expected of polyester. When the streak was completely melted, the sample was allowed to cool and recrystallize. On remelting, the higher melting streak could not be found. Experience indicated that polyester fibers could strike something during the spinning and drawing operations and develop a streak of highly crystallized, highly orientated material. This streak also had different physical properties and was causing defects.

A lot was accomplished, but feedback from the customer indicated they weren’t happy. It was assumed they needed more results and faster turnaround time. This was accomplished, but the relationship between the customer and us became more and more strained. Weekly phone meetings failed to produce resolution.

Finally, it was discovered in a face-to-face meeting that all defects were called slubs and not just those containing a streak of degraded polymer. This indicated one communication problem: we were not sharing the same vocabulary.

The second communication gaff was more basic. The fabric manufacturer didn’t care about the cause of the defects, while we, the polyester manufacturer, did. Discovering this problem prompted us to re-negotiate the price per pound of polyester downward. Suddenly, this defect level became acceptable.

It appears our original goals were as ill-defined as our vocabulary and we, like the office dwellers, were providing non-usable information.

I think I was the one holding up the card saying “in a.”

Communication between the microscopist and the internal customer can be at best difficult and at worst fraught with traps and landmines. One company experienced its own version of “To Tell The Truth” due to miscommunication between the microscopist and manufacturing plant.

Large, forty-seven pound metal wheels were the starting material in the fabrication of rubber-treaded bogie wheels. Wheel assemblies like the kind commonly seen on one end of a train car or on a tractor are often called a “truck.” Some types of wheels within the truck are referred to as bogie wheels (Figure 1).

We cured a thick, solid tread of rubber to the metal wheel for the manufacturer of large earthmoving equipment. The wheel acts as a support and tensioning device for large track-driven bulldozers like the one shown in Figure 1. Reports started filtering back to the plant about delaminations and catastrophic field failures.

Field failures, even when safety is not an issue, are inconvenient and very costly to construction companies. These same failures are a disaster to the component supplier who must adjust and replace these failures. It is quite possible, if the degree of dissatisfaction becomes high enough, to lose business to a higher priced supplier who promises better service and fewer field failures.

The field reports indicated the failures occurred in the summer in very hot locations like Texas and Las Vegas. These were new markets for the heavy equipment manufacturer. These problems were not reported in established markets like Minnesota or Maine.

Samples arrived in the microscopy lab and were inspected.

The bogie wheel plant was asked for details about the fabrication process and any recent changes made. The plant indicated nothing had changed in the process for several years. In short, the surface of the metal wheel was machined and painted with a metal primer. An uncured solid rubber tread with an adhesive layer was applied to the primed metal wheel and then cured. Samples of the material used in the process were requested and the plant efficiently supplied them.

Field failures are difficult to analyze. The failed component is often left in service until the failure is too great to ignore, or until it is convenient to remove the equipment from service for repairs. In many cases the microscopical evidence of the failure is worn away and a secondary cause of failure become the dominant process. What started as a separation at a spice line grows into tearing of stock suggesting poor dispersion. Surfaces quickly become contaminated with dust, dirt and degraded ground rubber. Additional damage can occur when removing the component. Improper storage can result in the formation of rust and cross contamination.

Initial examination suggested a possible cause. When the rubber tread was pulled away from the wheel, a fresh, uncontaminated failure was generated which resembled the original dirt encrusted failure. The newly created failure showed small smooth, shiny surfaces indicating trapped air. It appeared that air was trapped during the manufacturing process between the metal primer and the adhesive layer on the tread. These areas would concentrate stress as the rubber flexed between the metal wheel and the metal track under the weight of the bulldozer. Additional analysis suggested a mix-up in the order of the metal primer and adhesive, as if the adhesive layer was applied to the metal and the primer to the rubber tread. And what was that third mystery layer observed in some samples. Could the wheels have been reworked so the primer was applied twice? Had someone applied the wrong material? The plant said all of these scenarios were impossible.

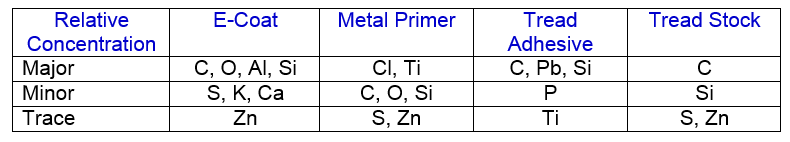

Cross-sections and thin-sections were cut and examined by light microscopy as well as SEM/EDS. EDS element data from standards were compared to the layers of the failed wheel. SEM imaging showed localized areas of electron charging, but considering the samples were uncoated and polymeric in nature, it was not considered surprising. A lot of information was obtained.

Despite all the data, a clear picture of the failure mechanism was not emerging. In desperation, the microscopy lab asked the plant to send additional samples from every step in the operation.

More of the same samples arrived, but a small postage stamp sized piece of folded paper was found in the bottom of the box. It was labeled “E-Coat.” This turned out to be our Rosetta stone.

E-Coat is a black plastic material the wheel manufacturer applied to the metal wheel to prevent rusting and contamination during storage and shipping. It has a non-crystalline melting point approximately 149°C, but softens at much lower temperatures. EDS on the E-Coat samples provided the information needed to clarify the order of the primer and adhesive layers.

A layer of material containing significant amounts of chlorine and titanium could be classified as metal primer. Tread adhesive contained lead and silicon, whereas E-Coat contained aluminum and silicon.

Additional analysis with IR Micro Spectroscopy confirmed the interpretation of the EDS data. The layers were applied correctly now that we knew the extra layer was E-Coat. It turned out E-Coat was less conductive than the primer or adhesive layers which made it easy to find in failed samples with the SEM.

The plant failed to remove all of the coating on the rough, pockmarked surface of the metal wheel. The metal primer coated the irregular metal surface and did not completely fill in the pockmarks. When the adhesive-coated rubber tread was applied to the primed wheel, many of the pockmarks were transformed into trapped air pockets.

The primer adhered to both the metal and E-Coat, but in the high summer temperatures of Texas something gave way. The E-Coat softened and started to pull away from the metal. This was expedited by the trapped air pockets which concentrated stress and the wheel failed.

The factory improved the machining to remove all of the E-Coat prior to metal priming and the problem vanished.

In hindsight the plant was asked about what they did to the metal wheel and they complied. It was only when I asked for information on all the processes performed on the wheel and samples from each one, that information was provided on the presence of E-Coat. It was clear to me that I failed to clearly communicate with the plant.

Today’s companies aren’t simply international, conducting business across one or two borders. They are truly global. The basic need to communicate across miles becomes trivial when dealing with differing time and cultural zones. Today’s technology provides a workable, if not satisfactory, solution to time differences and distance. However cultural differences remain a complication. Many companies address this impediment by exchanging personnel between different global offices. One such personnel exchange led to a growth experience between a German office director starting a two-year rotation and an American office supervisor.

The conversation went like this:

Walter (German director): I think you should buy a beamer for the office.

Sam (American supervisor): A Beemer?

Walter: Yes, a beamer. Do some research and get a good one.

Sam: A Beemer? And how should I pay for this?

Walter: (now becoming perplexed about what was a simple request) Just put it on the corporate card. I fail to see the difficulty in accomplishing this?

Sam: (sensing a problem) So, you want me to buy a Beemer for the office and charge it to the corporate credit card. What kind of Beemer should I get?

Walter: Yes! Yes! You know a beamer that projects computer images on the conference room walls.

Sam (now grasping the situation): Walter, in this country a Beemer is a BMW automobile.

To which the German responded: No, no… I’m not authorized for that!

I understand the American is still searching for a car that has a projector as a standard feature.

Noted image processing guru Dr. John Russ likes to point out a line from Arlo Guthrie’s “Alice’s Restaurant” to his students. The line goes, “…twenty-seven eight-by-ten color, glossy photographs with circles and arrows and a paragraph on the back of each one explaining what each one was…,” to remind us that as microscopists and scientists this is the way we communicate. If we are to improve processes and products as well as improve our understanding of the physical world, it with will only be through improved communication.

Comments

add comment