Characterization of Nanomaterials: Fitting the Approach to the Problem

Nanoparticles are defined as objects 1-100 nanometers in size in one or more dimensions. Due to their small size, nanoparticles have unique properties differing from those of their bulk analogues. The properties of a new nanomaterial must be assessed in order to determine how it will perform in a given application, what health issues might arise from exposure during manufacture and use, and how use and disposal will impact the environment. While nanomaterials hold these concepts in common, each one presents a unique characterization challenge.

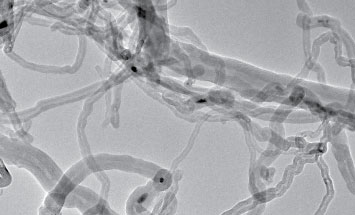

Analyses of nanomaterials typically require use of high resolution imaging techniques such as transmission electron microscopy (TEM) and field emission scanning electron microscopy (FE-SEM). However, light microscopy also has a role to play in characterization of nanomaterials, and techniques such as X-ray diffraction and Raman spectroscopy can contribute valuable structural information about these challenging samples. As with any analytical problem, the tools and the methodology must be matched to the questions posed. This is illustrated by two projects carried out at McCrone Associates, both involving characterization of carbon nanotubes (CNTs).

Case One

A project for a national regulatory agency involved fundamental characterization of over twenty commercially produced CNT samples. Techniques used included Raman spectroscopy and X-ray diffraction for structural and crystallographic information, SEM imaging with energy dispersive X-ray spectroscopy (EDS) for elemental analysis, and TEM imaging, EDS and electron diffraction to provide high resolution morphological, elemental and crystallographic results. This wealth of data gave the regulatory agency a starting point in understanding the chemical and physical nature of CNTs, and the range of properties present in a variety of typical commercial samples.

Case Two

An entirely different problem was presented by an industrial hygiene company that required monitoring of worker exposure during decommissioning of a CNT manufacturing facility. Over eighty wipes and filters were analyzed in a baseline assessment of CNT contamination throughout the building and in subsequent environmental and worker monitoring during cleanup.

In order to pinpoint CNTs among the common industrial particulate present in this large number of samples, and to provide the short turnaround time required, polarized light microscopy (PLM) was used to gauge the likelihood of CNTs being present in each sample, thereby limiting the number of samples requiring examination by higher resolution techniques such as FE-SEM and TEM. Development of this methodology was possible because the client provided a reference sample of the CNT product made in the facility. The reference CNTs formed aggregates that could be recognized by PLM as fine, dark particulate with a characteristic morphology. When PLM screening indicated presence of CNTs, the black particulate was isolated for analysis by FE-SEM or TEM to confirm presence of CNTs or to report that they were not found. Analysts were able to take advantage of a “bulk” morphological property to narrow the search for nanoparticles, thereby providing fast and reliable results for the client.

The need for development of flexible and innovative approaches to nanoparticle characterization continues to grow, and McCrone Associates has the range of analytical tools and the expertise to meet the challenge.

Comments

add comment