Freeze-Dry Microscopy and its Value in the Characterization Process

Freeze-dry microscopy, as part of a complete thermal-analysis study, is a valuable tool in the characterization of the thermal properties of any formulation. This process enables pharmaceutical companies to save a significant amount of time and money in pharmaceutical development and commercial manufacturing. Let’s investigate the information that can be obtained, as well as the essential equipment required.

Freeze-drying typically has three stages: freezing, primary freezing, and secondary freezing. During freezing, material is cooled below its eutectic point, the lowest temperature at which the solid and liquid phases of the material can coexist. The product then goes through primary freezing, the main step in the lyophilization process, which involves removing water from the frozen product. During this phase, temperature is critical—if too much heat is added, the material’s structure could be altered and spoiled. Finally, any unfrozen water molecules are removed during secondary drying, and the product is sealed.

Freeze-dry microscopy is critical in developing a lyophilization cycle. The first piece of vital information obtained is the identification of amorphous, and/or crystalline phases in the frozen system. This information is important because these different phases solidify and freeze-dry very differently, and certain steps in the freeze-drying cycle must be carefully designed during development in order to prevent the physical loss of structure. The next piece of vital information obtained from thermal characterization is the identification of the critical temperatures associated with the different phases. As formulations get more complex and specialized, so do the associated critical temperatures. When studying the frozen system, the critical temperatures that are routinely encountered are the glass transition temperature (Tg) and the eutectic melting temperature (Te). These temperatures identify the maximum product temperature that can be achieved during primary drying without risking structural loss of the product. Freeze-dry microscopy is well suited since the user is able to visually observe the physical loss of the structure as a function of temperature. The glass-transition temperature is typically followed by the collapse temperature (Tc) as the sample is warmed. Tc is best measured by freeze-dry microscopy. Most formulations exist in an amorphous state, and the critical temperature for freeze-drying will be their collapse temperature. By understanding the thermal properties of the product, the pharmaceutical scientist is prepared to identify, diagnose, and correct a problem such as collapse, shrinkage, and cracking.

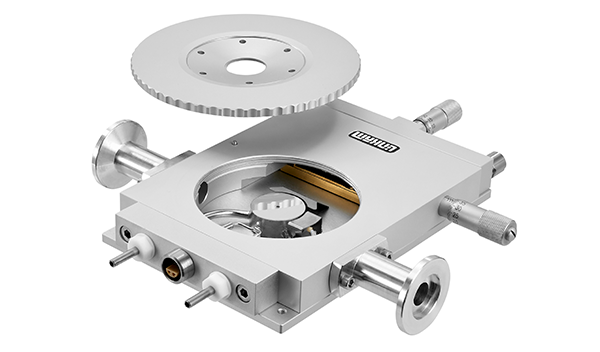

Necessary components for the standard freeze-dry microscopy lab include a polarized light microscope, a liquid-nitrogen-cooled thermal stage, a vacuum pump and an imaging system. The optimal polarized light microscope system includes a strong light source, a Bertrand lens, proper working distance objectives, and polarizer/analyzer.

Polarized light microscopy allows researchers to visualize critical temperature. It also allows them to determine if their sample is crystalline or partially crystalline based on the birefringence of anisotropic crystals within the frozen matrix.

Equally important is the thermal stage. An ideal thermal stage possesses these key capabilities:

- Temperature range of -195°C to 125°C

- Temperature stability less than 0.1°C

- Temperature accuracy of 0.01°C

- X-Y sample manipulation functionality

- Vacuum tight sample chamber to 10-3 mbar

- Silver heating block (ensuring high thermal conductivity)

With these components, formulators can determine the critical temperature before lyophilization begins, saving themselves time and money associated with trial-and-error freeze dry attempts. Pharmaceutical scientists can predict how their products will react under different thermal conditions and pinpoint the critical temperature so they can get lyophilization right the first time.

We can help you determine the optimal configuration for your specific needs. Speak with a knowledgeable technical representative.

Comments

add comment