Holographic Glitter

Abstract

Glitter is frequently encountered as transfer evidence (trace or associative evidence) in those crimes where there is intimate contact between assailant and victim. The transfer of cosmetic glitter to airbags in vehicle accidents may also help to show the seating positions of drivers and passengers. Glitter particles from different sources exhibit great variety. The more ways a questioned glitter particle may be characterized and compared with glitter from a known source, the smaller the subclass it will fall into and thus the greater its value as trace evidence. Many manufacturers of glitter include a product line described as “holographic glitter.” Holographic glitter achieves its color effects by virtue of regularly-spaced striae (gratings). These are not on the outer surface but instead are covered by a thin clear protective polymer layer. This article will illustrate how these striae may be detected, documented, and the striae spacing measured using light microscopy.

Introduction

Glitter has been previously reported as trace evidence and various methods for its characterization described (1-8). One immediately thinks of color, shape, and size. Shape and size are no problem, but color determination turns out to be quite complex. A thorough discussion of the science behind the perception of color as it applies to glitter particles is beyond the scope of this paper, but color in glitter particles is achieved based more on the principles of the optics branch of physics than through chemistry (dyes and pigments).

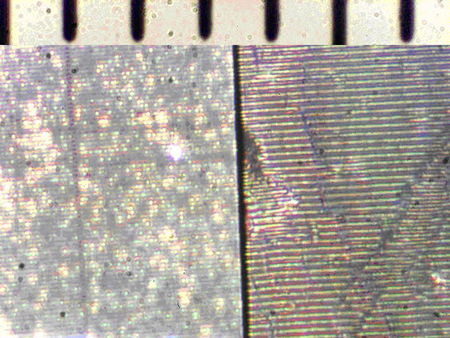

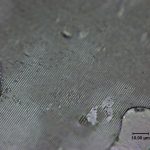

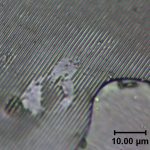

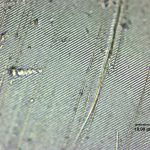

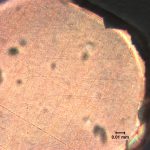

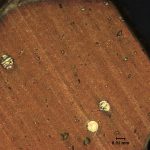

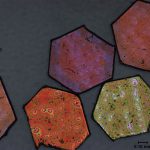

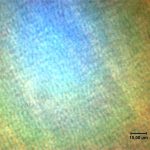

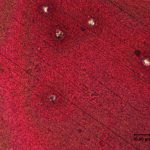

World-wide, there are well over a dozen different manufacturers of glitter. Many of these manufacturers offer a subclass described as holographic glitter. The determination that one or more questioned glitter particles fall into this subclass and the determination of their properties within the subclass can help discriminate between similar glitter particles and thereby greatly increase their potential value as associative evidence. The prismatic effect of holographic glitter is achieved through the interaction of light with gratings (parallel, evenly spaced fine striations just under a clear protective polymer layer on the surface of the glitter particle). These striations may be seen in the photomicrograph in Figure 1.

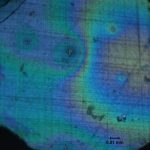

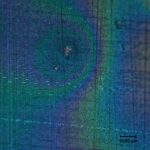

The determination that a questioned glitter particle is of the holographic type, and the measurement of the distance between striae may help to place the particle into a smaller subclass. Because the grating is not actually on the particle surface, the greater depth of field at higher magnification afforded by scanning electron microscopy is of no avail. This article will show that these gratings can be seen and the striae spacing used for the questioned and known particles compared using light microscopy at about 1000x.

Methods

All glitter particles examined in this study were purchased from Meadowbrook Inventions, Inc., 260 Minebrook Road, Bernardsville, NJ 07924 0960, USA. All were either from their product line Alpha Jewels HTMP or Alpha Jewels. They describe Alpha Jewels HTMP as “Precision cut Holographic Glitter particles consisting of Micro-embossed Aluminum particles designed for applications requiring Prismatic Special Effect with excellent Heat Resistance.” Alpha Jewels are described as “Precision cut Holographic Glitter particles consisting of micro-embossed vacuumed metalized (0.5% aluminum) polyethylene terephthalate, designed for applications requiring Prismatic Special Effect with excellent fastness properties. Solvent Resistant.” Alpha Jewels HTMP are further described as having a thickness of 0.001″ (25 micrometers) and a specific gravity of 2.4, with the Alpha Jewels having a thickness of 0.002″ (50 micrometers) and a specific gravity of 1.4. Alpha Jewels are offered in the following six colors: Silver, Gold, Strato Blue, Pink, Ocean Green, and Lavender. They are offered as square particles 0.008″ along a side; rectangular particles 0.035″ x 0.004″, 0.062″ x .0125″, or 0.125″ x 0.0125″, as hexagonal particles 0.008″ (one apex to opposite apex), 0.015″, 0.025″, 0.040″, 0.062″, and 0.094″. Also, specialized shapes are available as 1/8″ stars, hearts, or diamonds.

In this study the following 12 glitter products were examined:

[Sample numbers are not Meadowbrook Inventions numbers but were used by the authors in previous studies. Correspondingly numbered small samples were issued to the attendees at a workshop on glitter presented on 13 August 2007 in Clearwater Beach, Florida as part of a Trace Evidence Symposium sponsored by the National Institute of Justice and the Federal Bureau of Investigation.]

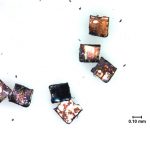

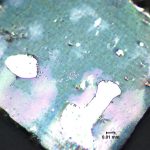

Sample #001 Alpha Jewels HTMP Silver 0.008″ x 0.008″ (Figures 2a-2d)

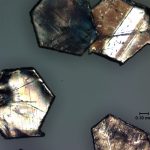

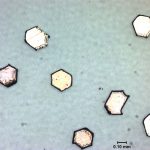

Sample #002 Alpha Jewels HTMP Silver 0.025″ hexagonal (Figures 3a-3c)

Sample #003 Alpha Jewels Silver 0.008″ x 0.008″ (Figures 4a-4c)

Sample #004 Alpha Jewels Silver 0.025″ hexagonal (Figures 5a-5c)

Sample #005 Alpha Jewels Gold 0.008″ x 0.008″ (Figures 6a-6c)

Sample #006 Alpha Jewels Gold 0.025″ hexagonal (Figures 7a-7c)

Sample #007 Alpha Jewels Strato Blue 0.008″ x 0.008″ (Figures 8a-8c)

Sample #008 Alpha Jewels Strato Blue 0.025″ hexagonal (Figures 9a-9c)

Sample #009 Alpha Jewels Pink 0.008″ x 0.008″ (Figures 10a-10c)

Sample #010 Alpha Jewels Pink 0.025″ hexagonal (Figures 11a-11d)

Sample #011 Alpha Jewels Ocean Green 0.008″ x .008″ (Figures 12a-12c)

Sample #012 Alpha Jewels Ocean Green 0.025″ hexagonal (Figures 13a-13d)

Glitter photos settings: The samples were prepared by dry mounting a small sample of glitter on a standard glass slide with no coverglass. The images were viewed with a Nikon MM-40 measuring microscope equipped with LU Plan objectives [5x (0.15 NA), 50x (0.55 NA), and 100x (0.80 NA)]. Illumination used standard tungsten bulb, reflected brightfield condition, no neutral density or polarizing filters were inserted in the light path. Photographs were taken with a SPOT-RT color CCD camera (model 2.2.1.) and SPOT version 4.7 software set on auto gain and auto exposure. Micrometer markers in the photographs were calibrated against a MicroRuler MR-1 (s/n 5-14) size reference standard.

Results and Discussion

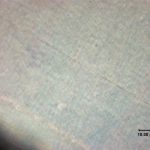

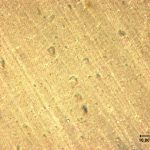

As seen in Figures 2 through 13 each of the twelve samples were viewed at three magnifications, 50x, 500x, and 1000x. This was done to illustrate that the gratings producing the prismatic effects can usually not be seen at low magnification. Although with some samples they can be seen at 500x, with many they are only clearly seen at 1000x. Parallel fine lines or scratches can be seen with many samples at 500x, but these are not evenly spaced nor are they parallel to the striae seen at 1000x. The parallel unevenly spaced scratches seen at 500x are surface scratches while the evenly spaced striations that produce the holographic effect are embossed on a vapor deposited aluminum layer that has over it a thin clear protective polymer layer. Glitter is cut from rolls of multilayered film. As with synthetic fibers, these thin sheets of multilayered film are produced by an extrusion process. In this process the extruded sheets pass over a series of rollers. Although just supposition at this point, the parallel but unevenly spaced lines or scratches seen at lower magnifications may be the result of the film passing over various rollers. If this were true, these lines seen at lower magnification could indicate the machine direction of the film before it is cut into glitter. As with synthetic fibers, this extrusion process imparts a partial crystalline nature so that refractive index with the machine direction may be different than across the machine direction. If questioned and known glitter particles are compared between crossed polarizers using a polarizing light microscope (PLM), it is important to bear in mind that glitter particles have two sides and that for meaningful comparison you must be comparing the same sides and the machine direction of the two when compared must be parallel.

References

-

- Grieve, M.C. (1987) Glitter particles – an unusual source of trace evidence? Journal of the Forensic Science Society, 27:405-412.

-

- Aardahl, K., Kirkowski, S., and Blackledge, R.D. (2005) A target glitter study. Science & Justice, 45:7-12.

-

- Blackledge, R.D. and Jones, E.L. Jr. (2007) All that Glitters Is Gold!. Chapter 1, 1-32, in FORENSIC ANALYSIS ON THE CUTTING EDGE: New Methods for Trace Evidence Analysis, Robert D. Blackledge, Editor, Wiley Interscience, Hoboken, New Jersey.

-

- Aardahl, K. (2003) Evidential value of glitter particle trace evidence, Masters Thesis, National University, San Diego, California.

-

- Kirkowski, S. (2003) The forensic characterization of cosmetic glitter particles, Masters Thesis, National University, San Diego, California.

-

- Weber, C. (2004) Glitter as trace evidence, Masters Thesis, National University, San Diego, California.

-

- Siciliano, M.A. (2006) Glitter as associative evidence: determination of individual particle thickness and density, Masters Thesis, National University, San Diego, California.

- Blackledge, R.D. (2007) GLITTER as Forensic Evidence, Trace Evidence Symposium sponsored by the NIJ and the FBI, Clearwater Beach, Florida.

Comments

add comment