Investigative Analysis Unveils Illusive Contaminant

Collaborating with you, our clients, to help solve contamination issues and product defects has been the mission of the scientists at McCrone Associates for over 63 years. We appreciate your trust in us and enjoy the investigational challenges associated with resolving your materials issues.

The use of light microscopy has been a key element of our mission to solve trace contaminant and materials identification problems. McCrone Associates continues to expand its microanalysis capabilities to maintain an ideal analytical laboratory for materials analysis. To this end, and to help you meet regulatory requirements, McCrone Associates is ISO/IEC 17025, GMP and GLP accredited for its microscopy and microanalysis methods.

Product defect analysis may include routine or compendial testing, however, investigative microanalysis is much broader in scope. Out-of-specification or contamination problems require an expert with the capabilities to thoroughly examine the situation. Direct collaboration with you allows our scientists to gain an understanding of your processes, needs, and goals, and is a critical first step. This understanding combined with our scientists’ expertise and experience leads to formulation of an investigational plan to isolate the material(s) in question (often from a larger sample matrix) and use multiple analytical techniques to ultimately provide a meaningful interpretation of the resulting data.

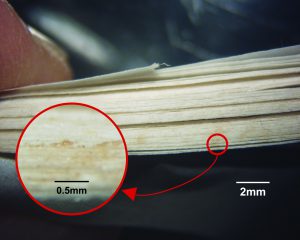

Recently, a pharmaceutical packager contacted McCrone Associates after noticing faint brown stains on the edges of large rolls of coated paper stock that were stored in its warehouse. The company suspected grease or debris from the warehouse environment as the cause of the stains.

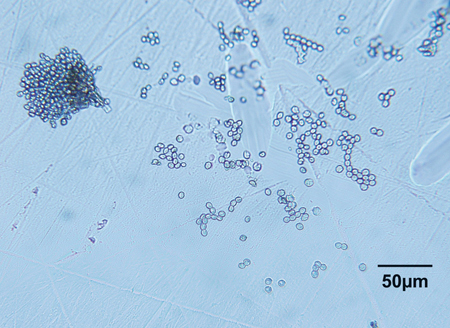

When the samples arrived at our laboratory they were first opened and examined in our Class 5 cleanroom. Working in this highly controlled contamination-free environment allows precise control of sampling conditions. Using a stereomicroscope, the stain was examined and found to consist of clusters of subspherical particles. When examined using a polarizing light microscope, the stain was found to be composed of hundreds of subspherical particles, 4 to 5 micrometers in size.

Once removed from the paper, the particles were pressed onto a potassium bromide crystal for infrared analysis. Infrared analysis established the presence of protein and carbohydrates. The chemical composition and visual appearance of the sample suggested biological material.

Further microscopic examination and staining with methylene blue identified the brown stain as fungal growth. Many rounded spores, chains and clusters of spores, and occasional fungal hyphae were seen in and on the paper sheet, and between the fibers. If left untreated, the fungus would result in unacceptable staining of the finished package. The pharmaceutical packager incorporated a fungicide in the paper coating formulation and implemented stricter environmental controls in the warehouse to solve the problem.

This is just one example of the power of investigative microanalysis practiced at McCrone Associates. Determining the source and identification of a contaminant requires more than routine testing, and our findings are often surprisingly different from what was originally suspected by the client. We value the years of experience we have gained working with a diverse group of clients and exposure to a wide variety of materials problems.

Comments

add comment