The Kofler Hot Bench: Repair of a Classic Melting Point Determination Apparatus

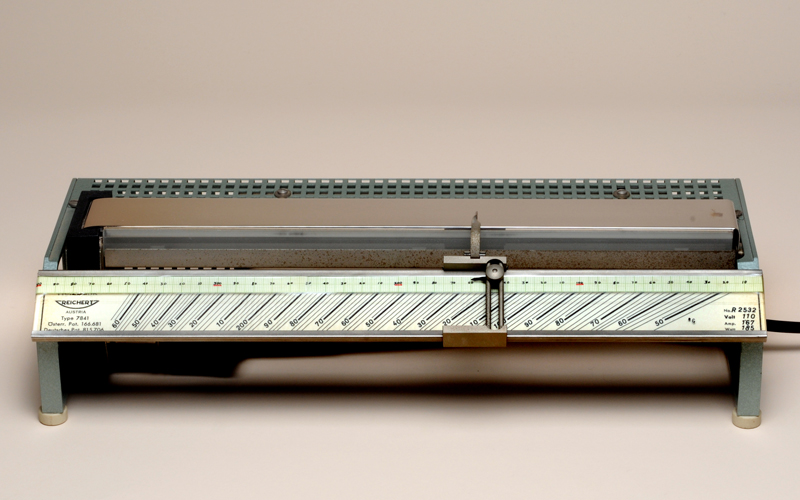

The Kofler Heizbank (heating bar; hot bar; hot bench) designed by Ludwig Kofler, manufactured by Reichert (Austria), and originally imported into the U.S. by W. J. Hacker (New York) is, basically, a 38 mm × 370 mm stainless steel surface which is electrically heated at one end, resulting in an approximately linear temperature gradient along the top surface. This hot bar, or hot bench, which has been used for over half a century, was originally supplied as one of three models covering the temperature range of 80°–180°C, 10°–210°C, and 50°–265°C, but the most useful for industrial and pharmaceutical use is the 50°–265°C model. Approximate temperature linearity along the stainless steel surface is actually accomplished by using several wedge-shaped bars of aluminum metal under the stainless steel surface. The different conductivities and shapes aid in achieving temperature linearity.

The heating current for the hot bench is stabilized by a special iron-wire resistance bulb manufactured by OSRAM. The bulb, which has a screw-in base about half the size of a common Edison base, screws into a socket which is beneath and behind the heated surface, under a shield, beneath a grating cover seen at the rear of the apparatus.

A scale with temperature lines every 2°C, together with a runner with pointer that can be moved horizontally along the front of the heated surface, and a rider that can be moved vertically, are provided for reading temperature. In actual practice, most users apply 1 mm grid graph paper over the scale, and write the temperature directly on the graph paper.

The hot bench is calibrated by using a set of organic chemical compounds as melting point standards. Calibration is initiated by either sprinkling a small quantity of the melting point standard along the surface of the bar, or, more commonly, by depositing a small amount of the chemical on the cooler side of the bar, and then moving it slowly toward the hotter end until a point is reached where approximately half of the chemical (on the left), is melted, and the cooler half (on the right) is not. The pointer is then moved to the sharp line that divides the melted from the non-melted sides, and the scale is marked with that known melting point temperature. This process is repeated with all melting point standards so that the entire length of the graph can be used to measure melting points.

The heating up time of the hot bench is about 40 minutes. Melting points determined using this hot bench will, in general, agree with those obtained microscopically. There will, however, be some deviations, particularly with unstable substances, because samples on the hot bench can be brought to their melting point in seconds, whereas melting points determined with the hot stage take longer to determine.

Specific applications of the hot bench have been applied to organic compounds in general, to explosives by McCrone (1957), and to pharmaceuticals by the Koflers (1954) and Maria Kuhuert-Brandstätter (1971). Maria Kuhuert-Brandstätter was an assistant to Ludwig and Adelheid Kofler when she was young, and eventually came to edit their work. As professor of pharmacology at the University of Innsbruck, Austria, she dedicated her book to Adelheid Kofler, “The widow of my highly-esteemed teacher Ludwig Kofler.”

The Problem with the Kofler Hot Bench

The one common, annoying, and unfortunate problem with the Kofler hot bench lies with the OSRAM stabilizer tube. This special tube was developed by Professor Dr. L. Kahovec, of Graz, Austria (Kofler, page 33), and, quite commonly, has the nasty habit of burning out; replacement tubes are no longer available.

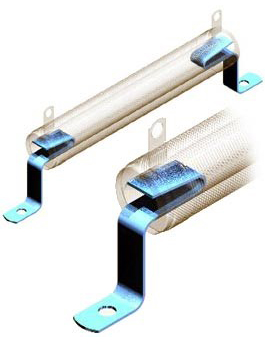

The October 1977 issue of the Journal of Chemical Education contains a four-line filler announcement at the foot of page 637 titled “Low-Cost Stabilizer for The Kofler Hot Bench.” The entry read, “The Kofler Hotbench (Reichert) uses a hydrogen-iron stabilizer to correct for any voltage change in the electrical supply. Since these stabilizers are no longer available we have found that a vitreous enameled resistor, Ohmite Dividohm Stock No. 0959, Watts 100, Ohms 50, Ohmite Manufacturing Co., Skokie, IL, 60076 is a suitable replacement.”

The Repair of the Kofler Hot Bench

The original OSRAM light bulb (stabilizer tube) has the following designation imprinted on the tube: OSRAM/KABA/25-75 volts 1.67A /2796. This calculates as 15-45 ohms. It can be replaced with a modern adjustable power resistor such as the Dividohm mentioned above. This resistor has an adjustable lug that should be set at 40 ohms using a meter, or about ¾ the length of the resistor.

Resistor #D100K50RE

Mounting Kit (6-1/2”) #6104-6 1-2

Mounting Kit (8-1/2”) #6126P-8 1-2

Similar resistors are made by several companies and sold by many distributors such as Digikey. They may also be found used on eBay. You will need to take the heat shield off the Heizbank. Drill out the rivets holding the internal shields, and mount the resistor to the perforated chassis. These resistors feature a hollow core to permit secure fastening with spring-type clips, or through bolts with washers. Mounting brackets may not be included with resistors, but can be purchased separately or made.

Next, cut the wires close to the original screw-in base, and attach one wire to the nearest resistor lug and the other to the sliding lug. This resistor gets hot (thermally) and also has hot electrical connections. Be careful to tie up the wires leading to the resistor because it gets hot enough to quickly burn off wire insulation. Remember to also tie up the power cord. Once everything is in place, calibrate the hot bench using melting point standards. You can adjust the resistance if necessary.

Click on thumbnails to see an enlarged view.

To conform to electrical standards, the heat shield should be replaced, and the unit properly inspected. Do not use this repair in an unsafe manner.

References

Kofler, Ludwig and Kofler, Adelheid; Brandstätter, Maria, editor (1954) Thermo-Mikro-Methoden zur Kennziechnung organischer Stoffe und Stoffgemische. Verlag Chemie, Weinheim/Bergstrasse, Germany. 608 p.

Kuhnert-Brandstätter, Maria (1971) Thermomicroscopy in the Analysis of Pharmaceuticals. Pergamon Press, Oxford, New York, Toronto. 409 p.

McCrone, Water C. (1957) Fusion Methods in Chemical Microscopy; A Textbook and Laboratory Manual. Interscience, New York and London. 307 p.

Comments

add comment