Overcoming the Top Three Challenges to Lyophilization

Greg Sacha, Ph.D., a Senior Research Scientist for Baxter BioPharma Solutions in Bloomington, IN, shares tips to help overcome the top three lyophilization challenges. Dr. Sacha also teaches a freeze drying course at Hooke College of Applied Sciences.

1. The effect of the API and formulation components.

Formulation development for small and large molecules requires different approaches. Small molecules may not require any excipients and may be more stable when prepared as dry as possible. Most large molecules will require excipients that protect them from freezing-induced denaturation and from the loss of water during drying. Freeze/thaw and agitation studies are easy and quick to conduct to determine if a large molecule is sensitive to aggregation as a result of freezing.

2. Choosing Primary Drying Conditions for an Initial Cycle

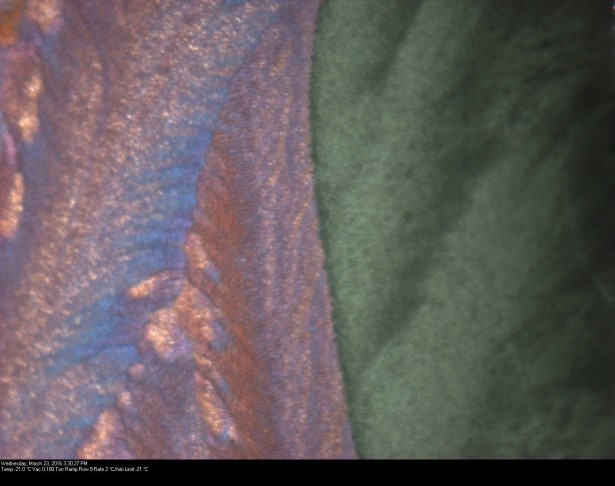

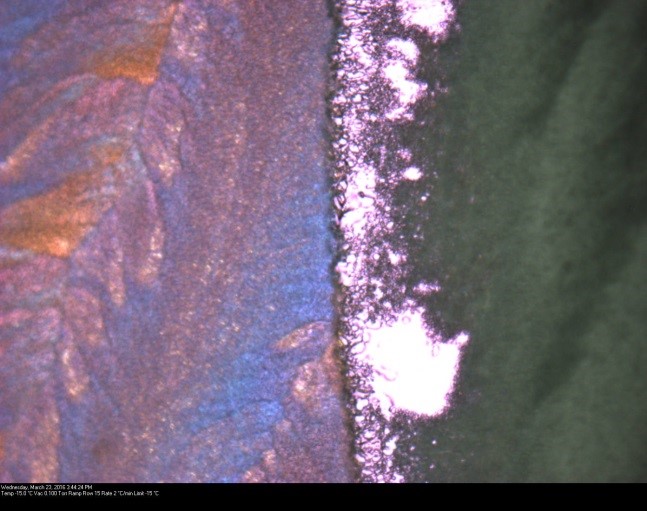

Formulation components affect the thermal behavior of the formulation. Examining the formulation using DSC and freeze-dry microscopy will provide data on the product temperature at which thermal events such as crystallization or collapse occur. This information will aid in determining if an annealing step is needed and will help determine an acceptable shelf temperature for primary drying.

3. Scale-Up and Technical Transfer

The nucleation temperature and product temperature will be influenced when scaling-up to a clean environment with much larger equipment. Conducting experiments at laboratory scale to determine the maximum acceptable product temperature during primary drying will ensure that the process is not operating on the edge of failure. This is extremely important when considering that the product temperature of vials located on the edges of a shelf will be warmer than for vials located in the center of the shelf.

A cycle developed in the laboratory may not be acceptable at full scale. This is largely dependent on the design and capability of the lyophilizers. Understanding the processing conditions that challenge the performance of the lyophilizers, such as encountering choked flow during primary drying, will prevent challenges during scale-up and routine manufacturing. The processing conditions that challenge the performance of a lyophilizer can be examined by subliming ice slabs and identifying the shelf temperature and chamber pressure combinations at which the chamber pressure cannot be controlled.

Comments

add comment