A “Poor” Microscopist’s Clean Bench

When working with minute objects such as micrometer-sized particles, fibers, metal and plastic fragments, debris, et cetera, it soon becomes evident that minimization of possible interference from environmental dust and other artifactual contamination from the shop environment is essential for undisturbed, reproducible and meaningful results.

In a professional setting (e.g., an aseptic manufacturing environment in a pharmaceutical factory or a semiconductor fabrication plant), much effort—and money—is spent to ensure proper conditions for these critical production prerequisites.

When working on such microanalytical topics in a home shop, it is not possible (in the majority of cases …) to spend that amount of money and effort. It is the aim of this little communication to share some experiences and insights from my home shop project of constructing a “poor” microscopist’s clean bench with the limited means that a hobbyist can spend (see Figure 1). Over all, less than 500 EUR have been spent on making the little device. An estimated 50 to 60 hours of work were necessary. For a list of all components, supplies, and parts used, see the end of this article.

The primary concept of the clean bench is to generate a particle-filtered, clean, positive pressure laminar flow of fresh downstream air inside a spacious box, separated from the rest of the home shop. This general concept is analogous to many similar, professional designs. The box is made from timber latches (5 x 3 cm cross sectional shape) that are cut into appropriate lengths and then fixed with metal corner brackets (see Figure 2) to build a solid framework that, when ready, reminded me of a hamster’s box! The overall outside dimensions of my bench are: length 100 cm, depth 65 cm, height 120 cm. This box is then plated on its outside with cut-to-fit cardboard of approx. 1.5 mm thickness, using staple clips to fix them onto the wooden framework.

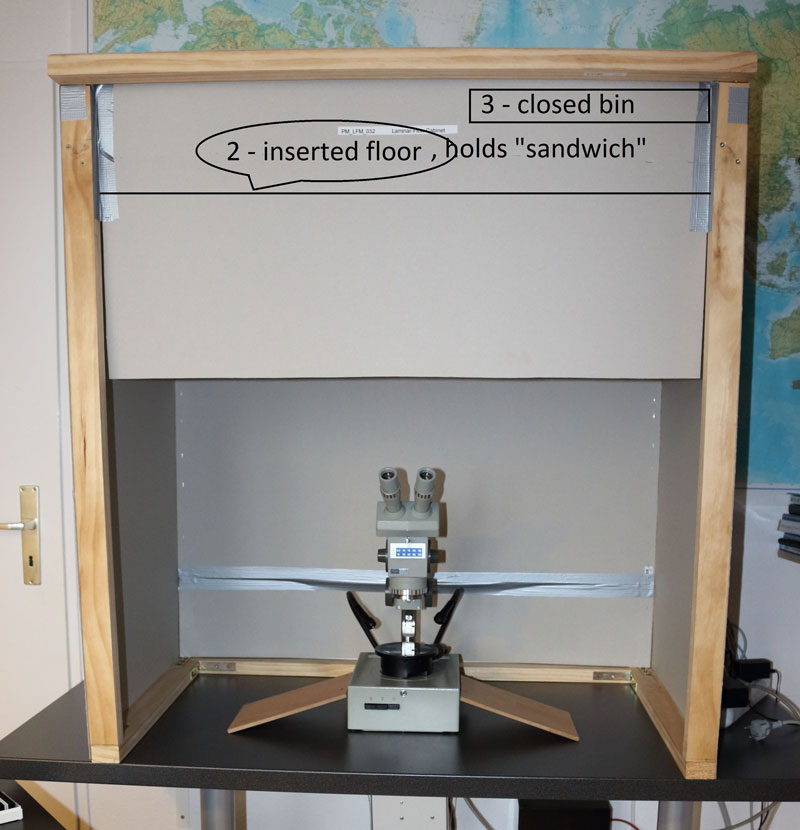

In the overhead part of the box, an “inserted floor” (detail 2 in Figure 3) was constructed that holds in place a “sandwich construction” made from two pieces of meshed metal baffle and a 0.5 cm thick layer of polyester fiber wadding between these baffles. The sandwich construction is sealed at all four sides with self-adhesive duct tape. The sandwich construction is sealed against the underlying clean space by putting it on top of a circumferentially glued strip of foamed sealing tape, such as used to e. g. tighten small crevices at your home windows. This ensures an air-tight seal and a positive pressure buildup above the sandwich construction while the fans are running. This sandwich construction is the main means for filtering the incoming air from the five fans; it releases the air particle-free in laminar motion into the inner box space beneath it.

The uppermost part of the bench (detail 3 in Figure 3) contains a closed bin with five venting fans on top (see Figure 4) as used for cooling computers and other types of electronic equipment. These fans are supplied with electric power from a small, commercial, 12 volt dc power supply.

Inside the as-created cabinet, a fluorescent tube lamp of commerce was fixed with some screws as a general means of illumination (see Figure 5). Fluorescent tubes that produce light of almost daylight quality were selected.

The as-built “poor microscopist’s clean bench” is placed on top of a wall-mounted kitchen workplate. My primary use of the home-made clean bench is sample preparation, mostly using a stereomicroscope. To facilitate a smooth and easy-to-clean working environment under the bench, a 6.5 cm diameter hole was drilled into the kitchen workplate and electric cables from the stereomicroscope, as well as the double-gooseneck light guide from a fiber optical illuminator, were then moved out of the way, down to the free space under the workplate. The fiber optical illuminator itself was also placed on the downside of the work plate in a hanging mount (see Figure 5).

Control of illumination for the different types of lamps can conveniently be arranged by using a foot switch, so that you can change illumination sources without moving your hands and eyes from the objects that you are working on. This highly useful installation has been adopted from a recommendation given by Delly in [1].

When planning your own clean bench, it is essential to allow enough space for your head to reach the eyepieces of the microscope you are using, even when using the binocular head of the stereomicroscope in its fully-raised position. Also, enough space to place your forearms (and sometimes elbows) under the bench is essential. It is advisable to make some measurements of these critical dimensions before starting to work on the construction project.

When working under the hood, protection from contamination originating from your own body is equally essential. Therefore, the use of a surgical mask and mob cap (head cover) as well as latex gloves and forearm protectors is highly recommended. Furthermore, a convenient and easy-to-reach supply of all instruments and accessories necessary is of great importance. I arranged for this by using a mobile file pedestal on which to put all the necessary equipment (and on top, see Figure 7).

Some practical (and legal) advice, at last:

- The author does not take any responsibility with respect to the use of the equipment in the way described here, you are solely on your own risk when using equipment of this type in this manner.

- The clean bench, as described herein, is intended for a hobbyist’s use, not for use in a professional surrounding/analytical laboratory.

Equipment and Materials Used

- Timber latches, 3 x 5 cm cross section, rectangular shape, cut to length as appropriate

- Metal brackets

- Wood screws of proper size

- Duct tape, self adhesive

- Polyester fiber wadding

- Meshed metal baffles of proper size, 2 identical pieces having the dimensions of the cross section of the clean bench hood

- Self-adhesive foam tape (as used to seal e. g. window crevices); “TESAmoll” of Beiersdorf AG, Hamburg, Germany used for project

- Cooling fans for computer equipment (5 pieces of “bequiet!® Shadow Wings PWM 140 mm” used)

- 12 Volt regulated dc power supply VOLTCRAFT FSP 1122, Conrad Electronic, Germany

- Fluorescent tubes lamp, 2 tubes of 90 cm length, 2 x OSRAM Biolux L 30 W/965, Osram, Germany

- Digital photographs shot with CANON EOS 700 D, Canon Zoom Lens EF-S 18-55 mm, 1:3.5-5.6 IS STM

Copyright for all photographs: Jan Burmeister, 2014.

Cited References

Delly, John Gustav. Essentials of Polarized Light Microscopy. Hooke College of Applied Sciences, Westmont, IL.

General Reference and Reading Suggestions

McCrone, Walter C.; Hertrich, James A. Clean Room Microscopy. The Particle Analyst I (1968), 17-24.

Comments

add comment