Quantitative X-ray Diffraction for Micro-samples

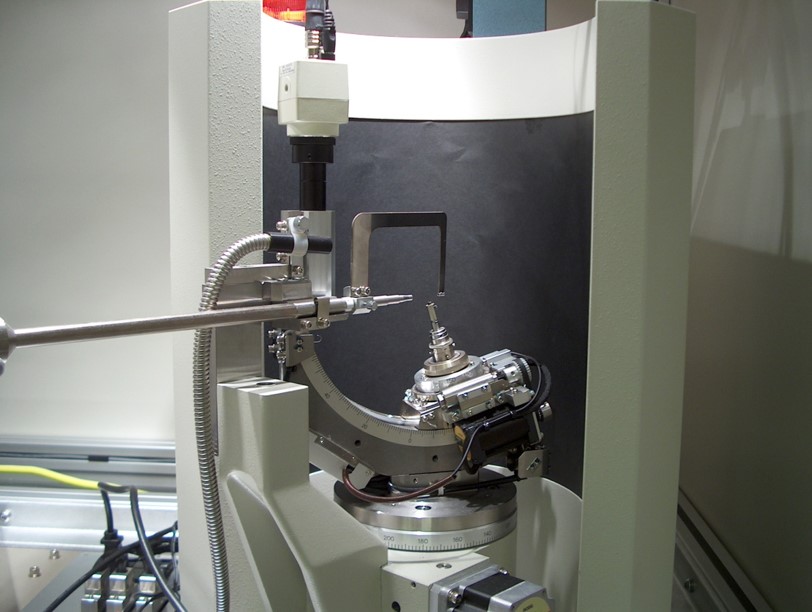

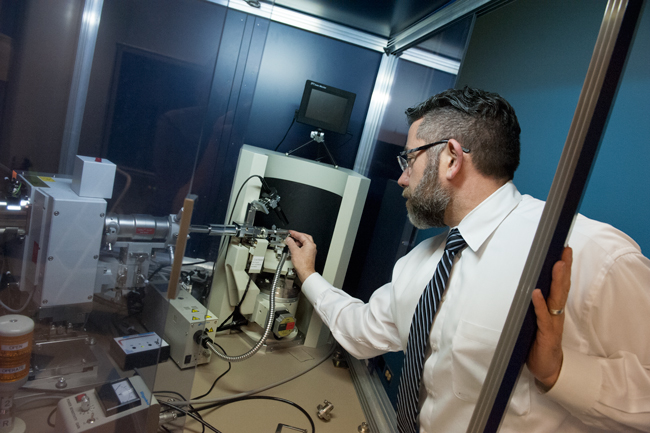

X-ray diffraction (XRD) remains one of the most reliable instrumental techniques for phase identification of crystalline materials. Particles in powder form typically contain enough randomly orientated crystals to effectively produce an XRD pattern that can be matched to a reference. With hundreds of thousands of references available for crystalline materials that include minerals, pigments, polymers, and pharmaceuticals, this would seem straightforward. However, challenges arise when the sample is not a collection of crystallites in a powder, but a single particle of several materials in the 10 micrometer size range or amounts of powder too low for typical systems (i.e., less than a milligram), for example, a small amount of corrosion located on a circuit board: the small amount of material and the need to remove the corrosion particles require an instrument that can successfully analyze a small sample size. The solution for such samples was developed at McCrone Associates using a rotating anode system coupled with a two-dimensional detector for expertly mounted particles (Swider). Additional challenges are evident when the amount of each crystalline phase is desired by quantitative XRD (QXRD).

Many XRD software companies have developed software for two major types of QXRD methods. One method relies on comparison to a reference known as the reference intensity ratio method (RIR). This method uses a standard material, such as corundum or quartz, to calculate an RIR value for a specimen. Many references contain an RIR value, but caution should be used when employing these standard values because acquisition parameters for your sample could be very different from what was used to collect the reference data. The best way to use the RIR method is to calculate in-lab RIR values on a case-by-case basis using the same sample and instrument conditions for both the standard and the material being investigated (Hubbard and Snyder).

The last few decades have brought Rietveld analysis to the forefront of XRD utilizing the increase in computing capacity for desktop computers. This method considers the entire pattern and all instrumental effects, not selected peaks for comparison as with the RIR Method. This method is also referred to as whole pattern fitting (WPF) or full-pattern analysis. More input about the materials is required for this method, and it has proven more accurate than other quantitative XRD (Rietveld).

Although these two applications to QXRD are useful, neither eliminate the practical issues with quantification, including particle size, homogeneity, and absorption. Particle size can usually be reduced to the optimal range of 5-10 micrometers by grinding, although this is unattainable in some cases, such as with concrete or metals . Homogeneity can be a huge issue with micro-sample sizes of 1 milligram or less and a beam of 100 micrometers. If the sample is analyzed in transmission (as at McCrone Associates), the issue of absorption is different than in a typical reflection instrument, and in some cases not as pronounced. In most cases all these factors can overshadow the improvements in pattern fitting and uncertainty is typically between 5-10%.

McCrone Associates considers all of these factors when approaching QXRD for clients, and uses state-of-the-art software for both the RIR and Reitveld methods. We work with clients on a case-by-case basis to determine how best to obtain reliable qualitative and quantitative data for micro-samples.

To learn more about analysis using XRD, attend the free webinar X-ray Diffraction – Solving Problems with Phase Analysis presented by Joseph Swider, Ph.D. on Thursday, July 20, 2017 at 1:00 p.m.

REFERENCES

Swider, J. R. (2010) Powder micro-XRD of small particles. Powder Diffraction, 25 (1), 68-71.

Hubbard, C. R. and Snyder, R. L. (1998) RIR–Measurement and Use in Quantitative XRD. Powder Diffraction, 3 (2), 74-77.

Rietveld, H. M. (1969) A Profile Method for Nuclear and Magnetic Structures. Journal of Applied Crystallography, 2, 65-71.

Comments

add comment