XRD–Mill McCrone

SKU:232-2

This is the perfect choice when preparing samples for subsequent x-ray diffraction (XRD) analysis.

The unique grinding action of the XRD-Mill McCrone rapidly reduces troublesome 0.5mm particles to submicrometer sizes required for quantitative and qualitative analytical methods.

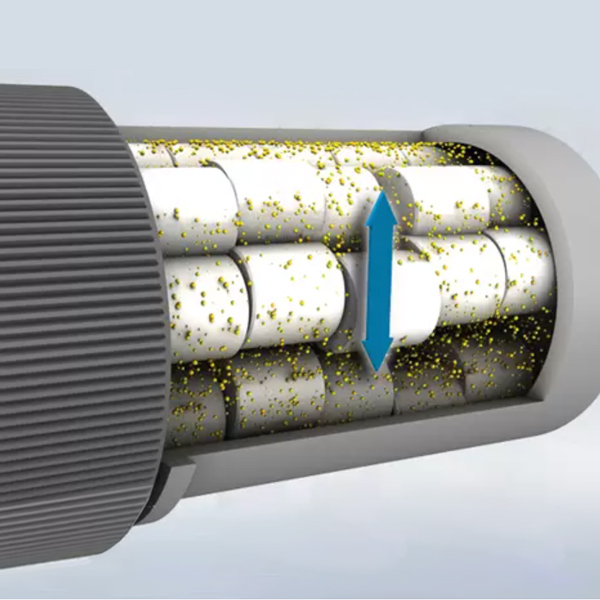

Forty-eight cylindrical grinding elements produce both line contact blows and planar shearing, in contrast to the random contact blows of a conventional ball mill.

Due to the very gentle size reduction process used by this mill, the crystal lattice of the sample is preserved.

The grinding vessel consists of a 125 ml capacity polypropylene jar fitted with a screw capped gasketless polyethylene closure. The jar is filled with an ordered array of 48 identical cylindrical grinding elements (8 rows of 6 elements each), available in agate, zirconium oxide or corundum. The grinding time for optimum micronization is between 3 and 30 minutes. A typical sample volume is between 2 and 4 ml.

Accessories and Options (pictured):

- Grinding jar with lid and pouring lid

- Agate, zirconium oxide or sintered corundum grinding elements

- Loading device for grinding cylinder

- Sample preparation kit (stainless steel percussion mortar, 10 sintered corundum cylinders, 1 sieve 500 µm, and a cleaning brush)

(Formerly the McCrone Mill)

The unique grinding action of the mill rapidly reduces troublesome 0.5mm particles to submicrometer sizes required for quantitative and qualitative analytical methods. Forty-eight cylindrical grinding elements produce both line contact blows and planar shearing, in contrast to the random contact blows of a conventional ball mill.

Slurry grinding by either corundum or agate grinding elements, both included with the mill, is the preferred method in most laboratories. Liquids used for slurry grinding include water, deionized water, isopropyl alcohol, or cyclohexane. Isopropyl alcohol and cyclohexane are recommended for clays.

The mill can accept up to approximately 4mL of material, although optimum grinding efficiency is usually achieved with a 2mL sample.

The advantage of our mill is that the analyst can examine the sample after a 10-minute grind and if it is not fine enough, put it back on and grind for an additional 5-10 minutes depending on size to be achieved. Many samples are ready after 10 min. and few need more than 35 min. grinding time.

The standard Mill package includes built-in process timer, 2 sets of agate grinding elements in jars with lids, loading device, extra mounting set, and pouring cap. As an option we can include a sample preparation kit—percussion mortar, sieve, corundum crushing pellets, and sieve cleaning brush—to provide the initial particle size of <0.5mm.

Features

Wet or dry grinding

Even particle distribution

Virtually no sample loss

Crystal lattice preserved during grinding operation

No chemical degradation of particles

Dimensions W x H x D: 205mm x 155mm x 520mm (8″ x 6.25″ x 20.5″)

Net Weight: 42 lbs.

Power (U.S.): 110-115V 60Hz

Power (Europe): 220-240V 50Hz

Grinder: Vibratory laboratory mill powered by a 1/30 HP motor

Speak to a Scientist

McCrone Group's analytical scientists are available to answer your questions. Have a project you'd like to discuss? Give us a call or email us!