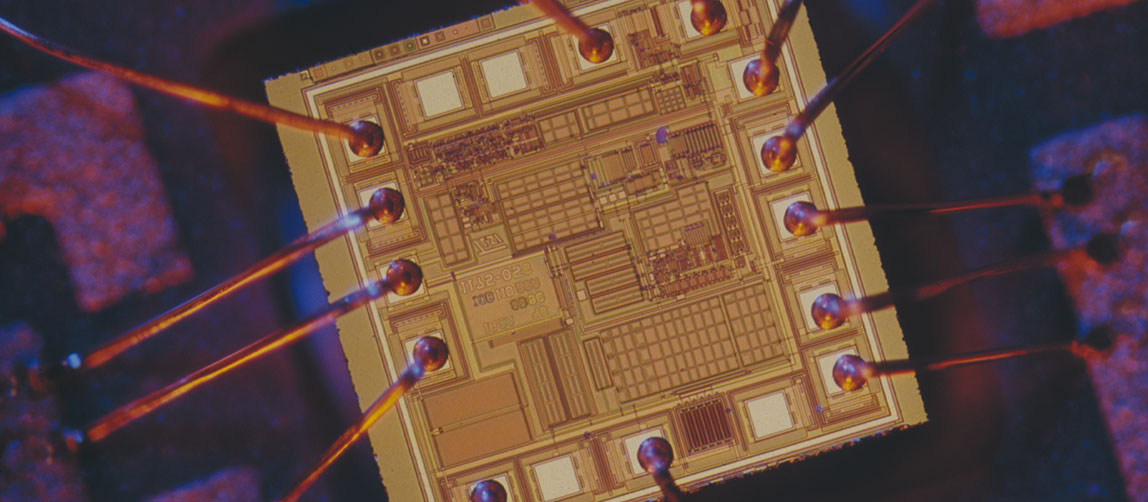

Electronic Devices

McCrone Associates has a long history of working with manufacturers in the development and production of electronic devices of all sizes, from stand-alone medical monitors to carbon nanotubes. Our laboratory offers in-house analysis using the latest instrumentation for electronic applications. Some of our recent investigations have assisted in solving problems for clients from a variety of industries and research centers, examining issues involving:

- Particulate identification on glass photomasks

- Contamination films and surface chemistry on ITO

- Material identification of optical waveguide components

- Surface analysis of soldering defects

- Identification of corrosion mechanisms on metal contacts and connectors

- Delamination and plating residues on flex circuits

- Characterization of CMP slurries

Our services begin with an evaluation of your problem and samples, and continue with analysis and consulting. If needed, we also offer on-site investigation and coordination of additional services.

Subject Matter Experts

Analytical Services

- Materials Characterization

- Contaminant Identification

- Product Comparisons

- Failure Analysis

- Surface Analysis

- Residue Analysis

- New Product Development

- Raw Material Testing

- Microstructure Examination

Common Samples

- Semiconductors

- Metals, Alloys, Solders

- Plastics and Polymers

- Surface Coatings

- Glass Vials and Containers

- Ceramic and Composites

Related Instruments & Techniques

- Fourier Transform Infrared Spectroscopy (FTIR)

- Comparison Microscopy

- Fluorescence Microscopy

- Interference Contrast Microscopy

- Polarized Light Microscopy (PLM)

- Stereomicroscopy

- Metallography

- Microtomy

- Scanning Electron Microscopy

- Transmission Electron Microscopy

- X-Ray Diffraction (XRD)

- X-Ray Spectrometry (EDS and WDS)