Manufacturing Defect Services

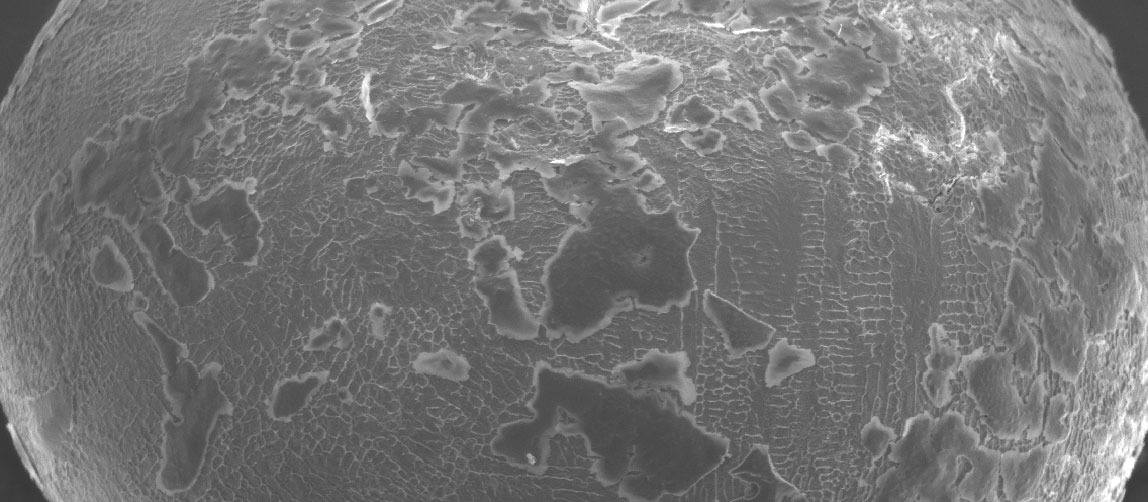

Manufacturing defects caused by particles and thin films often cause performance deficiencies. Our staff scientists use state-of-the-art instruments for specialized microscopy and micro-analysis. Ask us for a confidential evaluation of your problem, followed by reliable analysis and consultation. If needed, we offer onsite investigation and coordination of additional services.

Subject Matter Experts

Analytical Services

- Elemental Composition

- Compositional Distribution

- Chemical Compound Identification

- Identification of Inorganic and Organic Materials

- Product Comparisons

- Metal Alloy Identification

- Thickness Measurements of Metal Plating, Surface Treatments, Paints, Coatings

Common Samples

- Surface stains on metals, glass, plastics, paint

- Particle impurities on metals, glass, plastics, paint, pharmaceutical tablets

- Electrical contacts with highly resistive connections

- Failed adhesion/delamination

- Scuffed, scratched, gouged samples

- Particle inclusions in metals, glass, plastics

- Premature fractures

Related Instruments & Techniques

- Microtomy

- Particle Isolation

- Polarized Light Microscopy (PLM)

- Scanning Electron Microscopy (SEM)

- Energy Dispersive X-Ray Spectrometry (EDS)

- Fourier Transform Infrared Spectroscopy (FTIR)

- X-Ray Photoelectron Spectroscopy (XPS)

- X-Ray Diffraction (XRD)

- Transmission Electron Microscopy (TEM)

- Raman Spectroscopy