Quarter-Razor Blade for Hand-Sectioning

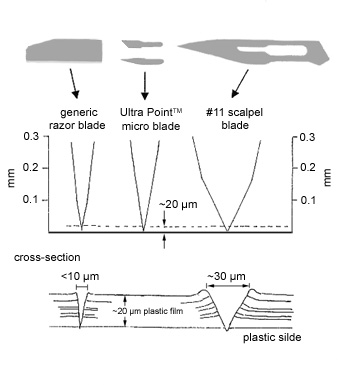

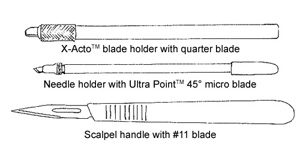

A custom-made quarter-razor blade is excellent for hand-sectioning multilayer plastic film, fibers or other semi-hard samples. A brief comparison of a custom-made “quarter blade” to two commonly used micro-blades, the Ultra Point™ and the #11 scalpel blade, is shown in Figure 1.

The thinner the blade, the less material it displaces and the better section it produces. The approximate displacement of a multi-layer polymer film by two of the blades is shown in Figure 1.

The tips of fine-pointed blades are weak. This is especially true of the Ultra Point micro-blade, because it is thinner than the #11 scalpel blade. For both horizontal and perpendicular sections, a blade does not need to have a fine point unless the sectioning is done under the polarizing microscope where the working distance is limited. Therefore, the quarter- razor blade with the rounded end is the strongest.

Making Four Quarter Blades from a Generic Double-Edged Blade

Step 1. First, the razor blade is cleaned. The oil residue from manufacturing is wiped off with soft paper and ethanol. Then both sides of the blade are carefully “taped” to remove the Teflon™ coating. The Teflon coating from the cutting edge is removed by brushing the edge with another “quarter blade.” If the coating is not removed, it could transfer to the surface of the section and confuse the result of the analysis.

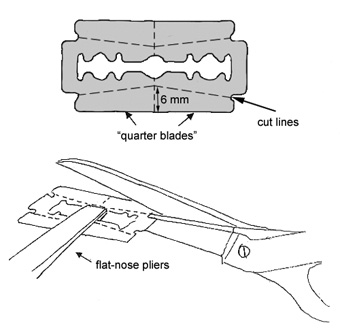

Step 2. The blade is held securely with a pair of flat- nose pliers and cut into four parts with a pair of heavy-duty scissors or tin snips along the lines indicated in Figure 2. The four cutting edges should not be touched by the cutting tools.

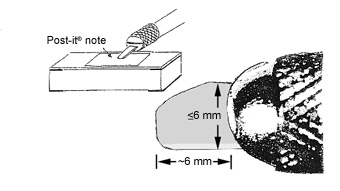

Step 3. The “quarter blades” are stored on a Post-it® note on a microscope slide or in a small plastic box. Double-coated tape should not be used because it holds the blades too tightly and they can be damaged when being removed.

Step 4. The blade can be put into an X-Acto™ knife holder as shown in Figure 3.

Note that the blade’s cutting edge is very delicate. To protect this edge, all hand-sectioning of multilayer plastic films or other semi-hard samples must be performed on a soft surface, such as a plastic slide.

Horizontal Sections Made with a Curved Blade

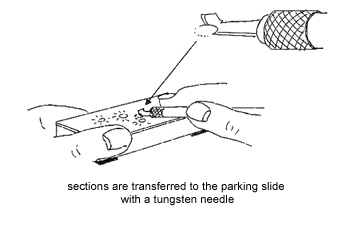

Surface defects in plastic films may give more information if they are sectioned horizontally with a bent blade as shown in Figure 4.

The procedure for making a bent blade follows: A “quarter blade” is held securely with a pair of flat-nose pliers and the blade’s flat side is pressed against a glass block until it snaps. It will always snap on the flat side if it is held by the non-cutting edge. Once the blade snaps, it will retain its bent position when it is put down. This step is illustrated to the left. Note that the blade should be bent in the opposite direction for a left-handed microscopist, see Figure 5.

The “quarter blade” fits into an X-Acto™ blade holder. The Ultra Point micro-blade fits into a needle holder, and the #11 scalpel blade fits into a No. 3 scalpel handle, see Figure 6.

The “quarter blades” are extremely sharp and care must be taken when handling them.

Comments

add comment