A Focus on the Linkam Modular Force Stage

Understanding the micro-mechanical and thermo-mechanical properties of materials is critical, as new and existing materials are continually being developed and altered to meet industry demands. Over the past few years, advanced materials like carbon fiber and graphene have become standard for products in the automotive, aviation, and medical device industries. It is crucial that physical properties be characterized and understood in order to optimize product performance.

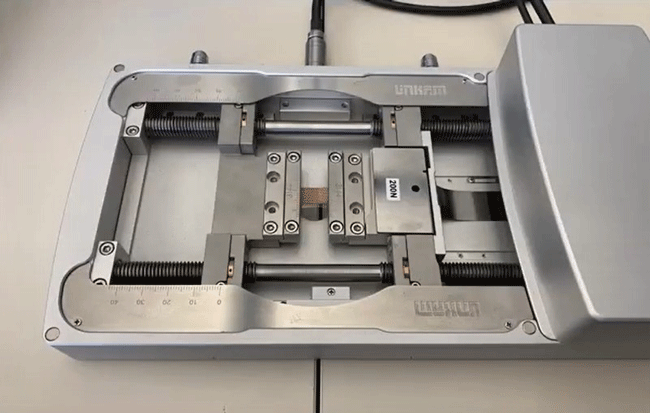

The Linkam Modular Force Stage (MFS) can be used in reflected or transmitted microscopy applications, as well as other techniques such as X-ray, Raman, and FTIR. The unique design of the stage also allows for humidity and electrical measurements. Some additional, exciting features include:

- Compression and Tensile Force – Test the compressive and tensile properties of your sample relative to temperature (-195°C to 600°C) and capture high resolution images of the structural changes in situ.

- Control Parameters – Speed of jaws, distance moved, and force applied can be varied relative to temperature and environment.

- Encoded Measurement – High resolution (1 µm) encoder for measurement of changes in length.

- Modular Design – Grips, force beams, heaters, lids, and heated liquid cells can be swapped to accommodate a wide range of sample types. Force beam resolutions of 2N, 20N, 200N, and 600N are available.

- Custom Options – Please contact us with details of your requirements.

For additional information on this exciting Linkam stage please watch these relevant webinars:

- Understanding Micro-Mechanical Properties of Your Samples Using the Linkam Modular Force Stage (MFS)

- Which Microscope Should I Use? A Multi-tiered Microscopy Analysis on Bandages/Wound Care Products

We are happy to run a demonstration for you – contact us today to learn more about this remarkable Linkam stage.

Comments

add comment