NeoScope vs. Full-Sized SEM

January 11, 2016

Presenters: Craig S. Schwandt, Ph.D., Director of Industrial Services and Senior Research Scientist, McCrone Associates, and Alan Vitous

For many materials, the results from the NeoScope benchtop SEM are equivalent to research grade systems that cost several hundred thousand dollars more and require their own room. There are reasons why you might consider a desktop SEM for your next purchase, and we’ll discuss those in this video. 37 minutes.

Transcript

Charles Zona (CZ): Hello and Welcome. My names is Charles Zona and I would like to thank everybody for attending today’s McCrone Group webinar. Our presenters today are Alan Vitous of McCrone Microscopes & Accessories and Craig Schwandt of McCrone Associates. Alan and Craig are going to compare the capabilities of the new JEOL NeoScope benchtop scanning electron microscope (SEM) to that of a traditional research grade SEM.

Alan has spent nearly 30 years selling various microscopy instruments, digital camera systems, and software. He is also well-versed in scanning electron microscopy and the operation of the JEOL NeoScope.

Craig is the director of industrial services and a senior research scientist with McCrone Associates and is also a co-instructor for Hooke College of Applied Sciences’ basic and advanced scanning electron microscopy courses. He specializes in x-ray microanalysis of particles using energy and wavelength dispersive spectrometry methods with the scanning electron microscope and electron microprobe.

Alan and Craig will field questions from the audience immediately following today’s presentation.

This webinar is being recorded and will be available on the McCrone group website under the webinars tab. And now, I will hand the program over to Alan and Craig.

Craig Schwandt (CS): Thank you, Chuck. Good afternoon everyone. We’d like to talk to you today about the benchtop scanning electron microscope. First, what is the normal need of a scanning electron microscope over an optical microscope? Well, generally you would want to use a SEM in order to have extended area coverage, extended depth of field, and higher magnification over an optical microscope. But we’d like to bring awareness of the current advances in electron optics technology, especially as it has been miniaturized to fit in the benchtop unit. And really, you have to ask yourselves some questions as you look towards purchasing a new instrument.

We’re going to divide our questions into groupings:

- The first one, do you do mostly imaging production of production line samples for quality control purposes?

- Or maybe you do analysis the same way?

- Or do you need the flexibility to do general science education to a wide group of audiences?

- Or are you more focused on doing investigative analysis and scientific research?

The first three questions really can be answered very well by a benchtop unit such as the NeoScope, whereas if you’re really involved with scientific research, maybe you need the flexibility of a full-sized tungsten ‘scope.

We are going to speak today really about comparing just the NeoScope or benchtop unit with a conventional tungsten microscope. We won’t venture into the field of field emission SEMs.

But, there’s really an overlap in the ability to take images that both these scopes can handle. We hope to share why you might really consider a benchtop for your next purchase.

Alan Vitous (AV):

Thanks, Craig. I am Alan Vitous and I am going to talk to you a little bit about the benchtop SEM system. I’m most familiar with the NeoScope from JEOL, so that will be the focus of what I am going to speak about today.

When I first started in this business, as Chuck said, almost 30 years ago, if you had told me that I could put an SEM in the trunk of my car and drive it around to customers and do demonstrations, I would have thought you were crazy. But technology has come quite a long way and we really have come to realize that the benchtop SEM system is really quite a good instrument.

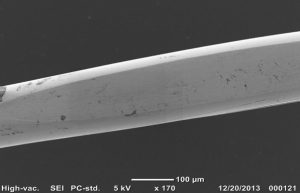

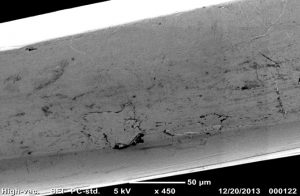

We found that production and manufacturing environments produce very good applications for benchtop SEM systems. This slide shows a specimen from one of our customers. This is a company that makes wire for specialized applications, and they wanted to get a good image of some flat spots that are appearing on the wire. And what we first did is we used optical microscopy, as you see up on left-hand side there, and it takes quite a bit of manipulation, fine-tuning of the instrument. You really have to know what you are doing with an optical microscope to get a decent image. Conversely, we just put the piece of wire on a piece of carbon tape and put it into the SEM and booted it up, and we got very nice images almost instantaneously. So, we have several customers that are using the benchtop SEM in this sort of application. In fact, we have one customer that runs two NeoScopes for 24 hours a day, seven days a week.

This same customer as in the previous slide, while they had the piece of wire in the instrument also wanted to confirm the composition of the wire. So, they wanted to look at the ratios of chromium to iron to nickel and make sure that the material was exactly what it was supposed to be. It’s very easy to do once you have it—the specimen—in the instrument. You can do imaging; you can do elemental analysis. It saves time and you don’t need two instruments.

For science educators out there, the applications are fairly obvious. You have high resolution, high depth of field, high magnification. The images here—you would have a hard time getting very good images like this on an optical microscope. For very little effort you can put these specimens in an instrument and get these very nice high resolution images. Hooke College of Applied Sciences here offers an introductory SEM course and the benchtop, as well as a full-sized SEMs, are utilized in the course. We also use the NeoScope as part of our local outreach programs to high schools to provide awareness for our 3+1 program with the chemistry departments of North Central College and Concordia University. I can see that the NeoScope or benchtop SEM system like this would also be very beneficial to universities with a core imaging facility to take some of the pressure off their larger instruments. For lower mag, lower resolution applications, this instrument is very proficient and it leaves extra room on the larger instruments for more advanced applications.

Keep in mind that some biological applications may require critical point drying in order to get good images. The upper left is a jumping spider that was coated; I am sure that was coated in gold (Au). The upper right is an image of the antenna of a moth and the lower center is actually the underside of a pine needle showing the stomata there and the little ribbons of fungus on the surface of the pine needle.

Sometimes manufacturers make a product and they need to see how it shows up; how differences in the manufacturing process will affect the final shape. How will it affect the final product? Is the shape what they wanted? Is it too large? Is it too small? Does it clump? These issues will affect how the material may dissolve or how it may coat a surface. So, the NeoScope is a very good instrument for this sort of application where you have an unknown and you want to gather more information on it.

CS: So, today’s benchtop SEMs really produce amazing images; some of those you’ve just seen. They really are an order of magnitude better than systems that are only a generation older. We really want to have a comparison of the qualities of a benchtop system with a full-sized system. One of the first things you can see, on the left we have an image of the NeoScope, of course it doesn’t have the PC associated with it, but you see a full-sized set up in a laboratory, a purpose-designed laboratory, and you see it takes quite a big footprint. There are specialized electrical requirements for the full-sized SEM, there’s the requirement for chilled water if you have a diffusion pump, and then just the overall size space.

I have shrunk down the NeoScope here to represent—it’s scaled really to the size of the sample chamber. This is the size of the NeoScope relative to the sample chamber of one of the JEOL variable pressure systems with the large chamber size. But, right there you see one of the biggest factors. If space constraints are a major factor for you in your consideration of an SEM purchase, there it is hands down.

If we look at the specifications of each of the instruments—this is a really busy slide, I realize—but, a few things to point out. We get a little variation in the accelerating voltage and some variability versus fixed. The secondary electron detectors are very similar. The backscattered electron detectors in the NeoScope are the same as that offered in the current tungsten series that JEOL offers. There’s a little bit of difference in terms of the stage, but the rest of these really come down to either sample size, or room size, or portability. These can be boiled down to a pros and cons list. You might consider a full-sized SEM to be more important if you require extreme imaging and analysis flexibility, for example, if you needed to add more detector options that couldn’t be added to the NeoScope. But, the con with that is then you have to have a purpose-designed lab and the instrument is, for the most part, fixed in the laboratory itself. Whereas with the NeoScope, you can have secondary backscatter and EDS microanalysis capability in a semi-mobile platform that you can move from one location to another, and it fits into many existing office or even production spaces, so you don’t need a purpose-designed laboratory for that ‘scope.

We will do a little bit of side-by-side comparison, although it’s not direct. The image from the NeoScope, on the left (below), is actually a backscattered image. Traditionally, backscattered imaging was not quite up to par with the secondary imaging, but here you can see almost no difference between the backscatter image acquired in the NeoScope and the secondary image acquired in a tungsten full-sized instrument (below right). If we increase the magnification, they’re not direct, the image from the full-sized is the same sample, that same diatom, and the NeoScope is of another granular material. You see the resolution is still very nice. It’s actually quite extraordinary. It beats most imaging of conventional tungsten instruments more than 10 years old. It’s pretty difficult to achieve nice images like this at 40,000X.

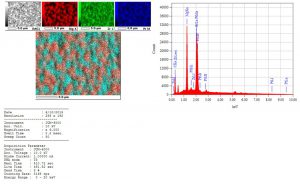

The microanalysis capabilities of the NeoScope are very impressive, as well. In this case, we’re going to compare, briefly, just some analysis of a powdered zeolite specimen. It was just placed onto a carbon tab and then carbon coated to avoid some of the charging, although because the grains are not entirely connected to one another, there is a bit of charging. On our analysis, though, we see a nice spectrum, it’s clean. We see the major components, the oxygen, sodium, silicon, and zirconium. And we can compare this with the same material analyzed in our JEOL 6480 with an Oxford Instruments Aztec system running an X-Max detector, and the spectra look very similar.

If we want to actually quantify those data, then we see results that are essentially the same. There are some differences in the lighter elements, but these differences can be ascribed to both the geometry affects having this mounted as a free powder, and also the charging, and also each of the systems use their own proprietary quantification algorithms. So, there are some differences from those results, but overall, the results are really very good.

AV: As we mentioned before, one of the main reasons for a benchtop SEM is the ease of use. It has a very small footprint; as you can see, it doesn’t take up much space at all. In the picture in the upper left here you see the main unit and the CPU with touch screen right next to it, and on the floor would be a power supply and a vacuum pump. The filaments for the system are a cartridge-type filament. It’s a tungsten-type filament and Wehnelt cap, all-in-one, and it plugs in just like a light bulb. It takes about five minutes to change a filament. The customer that we have that is running two NeoScopes 24/7 use one filament about every two months. A package of six filaments costs about $1500. That’s really about all you have to do for consumables on the instrument.

The NeoScope operates from a touchscreen control. Of course, you can also use a mouse. You can see that on the surface of this controller, you have both automatic and manual controls for alignment, focus, stigmation correction, and brightness/contrast. You can also do some minor rotation and image shifting in this situation as well. At the very bottom, you can see the observation conditions, or the imaging conditions. It’s a little hard to see, but you can see that right now, on this image, we are at high vac; we have a secondary image. We are running at 15 kV with a standard filament setting, and a standard probe current setting. You can also set from the top controls on the upper left of this the control panel here, the tags or labels that will be appended to the images as you save them. You can describe where you want to save the images, so if you wanted to attach the instrument to a network drive, you can save your images to network drives and do other sorts of mechanisms, set-up mechanisms, for how you want the instrument to start up.

As you can see, the NeoScope provides some very nice secondary electron images. These are actually some pollen grains that we were looking at, and you can see at the various magnifications, even as we go up as high as 40,000X, we have some very nice, crisp, sharp, highly-detailed images with some pretty good contrast.

Backscatter images also tend to be very nice. We have the diatom specimens that we saw a little bit earlier, as well as couple of other applications that we took images of, and we’re really very pleased at the quality of the backscatter images. The new NeoScope PLUS has an improved backscatter detector that allows you to do composite, topographic, and shadow imaging, as well.

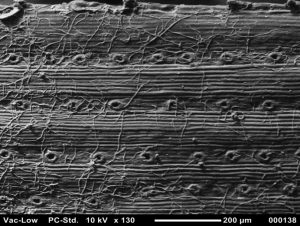

The low vac images from the NeoScope are really quite extraordinary, out of such a very simple instrument. Low vac can be used very nicely to mitigate charging situations. In the bottom right, you’ll see that that is a much-magnified image of the pine needle that I showed earlier. You can see the stoma, the fine detail around the stoma, and the little strings of fungus that are on the surface. You can see the septations between the hyphae.

If you wanted to do elemental analysis, the NeoScope also provides the ability to do elemental mapping. You can look at your specimen and determine what elements or what materials are in what area of your specimen. Again, this is a very handy application to have, especially in manufacturing where you are trying to determine what may be in certain layers, for instance, if you have layered specimen or if you have coatings and want to make sure that the appropriate materials are where you think they are.

You can also use mapping to tell you little bit about the material, as far as, whether or not it’s homogeneous or heterogeneous. You can overlay three different colors, three different maps, into one composite image.

If you wanted to learn more about the NeoScope benchtop SEM system, if you want to arrange for a demonstration, or if you would like to send me some specimens that I would be more than happy to run on the instrument, please contact me. My information is there. Or if I’m not available, you can call Jeff McGinn. He’s the manager of our group and he can arrange for a demonstration or to look at specimens, as well.

CZ: Thanks, guys. That’s very interesting. I would like to thank everybody again for attending today’s webinar and if you have any questions go ahead and type them into the question box there and we will get to those shortly. As you can see, we have several courses coming up in 2016—electron microscopy courses: SEM in March and October; then there are a couple of advanced SEM courses—we offer an imaging and X-ray microanalysis; and also transmission electron microscopy in April and October along with some upcoming webinars. The next one actually is “So, You Think You Are a Scanning Electron Microscopist?” by Joe Rebstock. That should be interesting.

Let’s take a look now at some of the questions coming in.

One question here, “Are you going to show or talk about the backscattered electron imaging from the benchtop?” I think Craig kind of touched on that a little bit. I don’t know if there’s anything to add to that.

CS: Again, the newest version of the NeoScope will come with the same backscatter detector that the new JEOL IT-100 and IT-300 have on them. It utilizes the same multi-segment solid state detector that’s on there. So, as sort of a JEOL proprietary option that offers compositional mode, topographic mode, and the shadow mode which is a combined backscatter and topographic, compo-topographic, combination that gives the backscattered image a three-dimensional affect to it. The imaging is, as you saw, some of those in low vacuum mode, those images were all acquired with the backscatter detector, and they’re very good.

CZ: Okay, several questions coming in regarding the cost of the NeoScope. Alan, maybe you can handle that one.

AV: Sure. The NeoScope with EDS is just under $120,000. That’s a turnkey system. That includes the CPU, the main unit, the power supply, and the vacuum system. I’d be more than happy to talk to anybody about their applications and write them up a full price quote, but we didn’t want to make this into a sales presentation. I would be more than happy to talk to you in private about your application and give you additional information, including pricing.

CZ: And when you say turnkey system, Alan this is another question here, does that include the EDS?

AV: Yes, just under $120,000 includes a full EDS package. No other modification to a room is required. You just plug it into your wall and away you go.

CZ: Anything to add to that, Craig?

CS: I just wanted to point out that this is what our intent for the webinar was: to have you evaluate your needs in terms of a laboratory or office space, the overall cost trade-off for a system, and when you’re considering the price, not only do you have to consider the price of the instrument itself—so a full-size one maybe you are talking in the neighborhood of $300,000+, and then for both the SEM and a nice EDS system—but then you have to consider adding in the modifications to your lab and preparation. In some of the cases you need a special electrical circuit, so that might have to be added in, and then just having the extra room space.

AV: There’s also the issue that the NeoScope is very easy to use for the uninitiated scanning electron microscope user. It’s very easy to use, very intuitive. When you talk about a $300,000 instrument, you really have to be sure that you know what you’re doing and that you can operate it properly. Which also ties into Hooke College—we have some very nice courses that will teach you exactly what you need to know for SEMs.

CZ: Thanks, guys. This one from Ed, “What is the chamber size and working distance of the NeoScope?”

AV: The chamber of NeoScope will accept a specimen of 70 mm in diameter and 50 mm high.

CZ: Okay. “How much does vibration affect the NeoScope imaging?”

AV: Vibration is going to affect any instrument, so you want to make sure you have it on a very stable surface. There is vibration dampening a bit in the main unit, but it would behoove you to keep the vacuum pump on the floor. Hopefully, your lab isn’t next to railroad tracks! Common sense prevails. But, you will see issues with vibration if the situation is bad enough.

CS: That brings up another point, though. In addition to vibration, there are other electromagnetic concerns, so unless you’re doing a full change control risk assessment of where you’re going to locate your full-sized SEM, you may find that you’ve put your lab into a very inappropriate vibrational and electromagnetic environment. Once you have a full-size system, you can’t move it, where at least with a NeoScope or a benchtop unit you can take it to another room and if that room meets your vibration and EM noise requirements better, then here you have a solution. Otherwise, you have a more costly solution in terms of corrective measures for the full-size system.

CZ: “Does the benchtop model meet ASTM guidelines?”

CS: Is there a particular guideline you have in mind?

CZ: I guess we’d need a bit more specific question, a little more detail on that question.

“Do all biological samples need to be carbon or gold coated?”

AV: Not necessarily. You can coat them with carbon or a metal, but the low vacuum mode on the NeoScope, as well as on a full-size instrument, is very handy in mitigating charging that will happen with a lot of biological specimens. If elemental analysis is important to you, you would probably lean more towards a carbon coat, because at least you know you can remove that spectra from your from your analysis.

CZ: Looks like there’s a question, “The EDS of samples with heavier elements—are there any limitations on that?”

AV: You can go from boron to uranium.

CS: There is a little bit of a limitation in that accelerating voltage is limited to 15 kV. But if you are judicious in your selection of lines—x-ray lines—you can pretty much establish an analysis of most samples. There might be a couple of samples where there would still be an overlap that might be a question, but for the majority of samples, 15 kV will provide you with the answers you are seeking, especially if you have standard reference materials that you compare your unknown to.

CZ: There is a question of regarding cross-sectioning applications and film build analysis; maximum 15 kV, is that correct?

AV: Yes, the NeoScope is limited to a maximum of 15 kV.

CZ: Here is one from Anna, “When replacing the filament, is alignment needed of the filament?”

AV: After you go through the replacement procedure, and you boot the instrument back up, it goes through an automatic alignment, so there is no other physical alignment needed. As you go through your analyses, depending on your specimen and the topography of the specimen and such, you can always manually touch up the alignment electronically as you’re going. Especially if you are going to be doing EDS, you will want to make sure that you have a good, strong signal. But in general, once you put in a new filament it is aligned automatically.

CZ: There are several comments here, some people who joined us later in the program asking if this presentation will be available. It will. It’s being recorded, so in about a week’s time or so, you’ll be able to listen to the recording on our website under the webinars tab. There will also be a transcript available if you would like to print that out.

Here’s a person who is interested in forensic applications: GSR, and bullet land and groove comparisons.

CS: Comparing the tool marks on the bullet would be fine to do with a NeoScope, but the stage of the NeoScope isn’t really automated to do gunshot residue analysis. That would be an application where you would either want to have a full-sized SEM with an EDS system that has the gunshot residue package, or you would want to buy a purpose-automated SEM, such as one formally packaged by Aspex (now by FEI), where you can look at particles on an automated basis rapidly. It wouldn’t be good for GSR, but it would be fine for examining the tool marks.

CZ: There’s a question here, “Does the JEOL have an automatic stage?”

AV: Not on the NeoScope. Not as of yet, anyway—it’s a manual X and Y, and does have a motorized tilt and rotate, but there is no automatic computer-controlled stage at this point.

CZ: Okay. Kevin wants to know, “Are you aware of any forensic labs using a NeoScope rather than a full-sized SEM?”

AV: I don’t have a forensic customer using this system; that doesn’t mean they aren’t being used. Through the McCrone group, I don’t have a good contact for a forensic customer.

CZ: Okay, I think that just about does it for all the questions. I’d just like to thank everybody again for attending the webinar today, and be sure to join us on January 21 with Joe Rebstock and his presentation, “So, You Think You Are a Scanning Electron Microscopist?” We hope to see you there. Thank you.

Comments

rberdan@scienceandart.org

$120,000 US is a lot of money for a microscope that only offers image resolution of 1280 pixels! This needs to be addressed, and frankly the cost still needs to come down a lot before individuals or private folks consider purchasing one. I would rather pay $100 an hour to use a full SEM in our local University—though I would like to own an SEM in my studio. I will have to wait until the price drops significantly and the resolution of the digital images is at least 12 Megapixels. Also would be nice if the sellers posted an approximate price on their web sites, this if the first mention of the products price I have been able to find on the net—and it clearly puts it out of my price range and many others. The size of the unit and usability appear good, but the image quality looks noisy at best. I hope the companies developing this product work toward reducing the price and image quality further so that the SEM can become as common as a light microscope.

Replies

Leslie Bolin

Thanks for your comment! With image resolution down to 15 nm, and an EDS detector with resolution <= 133eV (Boron to Uranium), the Neoscope is the perfect complement to light microscopy. We invite you to send us samples so that we can show you the exciting features and image quality of the instrument.

add comment